| Home | About Us | Our Products | Contact Us |

|

|

|

|

Magnetic Separators Overband Permanent Magnetic Separators Liquid Line Magnetic Separators Wet High Intensity Magnetic Separators High Intensity & High Gradient Drum Separators High Intensity & High Gradient Roll Separators High Tension Electrostatic Drum Separators Magnetizer And Magnetic Devices Electro Magnetic Scrap Drum Separator Star Trace Benefication Plants Overband Permanent Magnetic Separators Motorized Linear Vibratory Feeders Magnetic Linear Vibratory Feeders Extra Heavy - Duty Vibrating Feeder High Intensity High Power High Bullet Magnet |

Overband Magnetic Separators

Overband Permanent Magnetic Separators |

| We are one of the highly established manufacturer and supplier of overband permanent magnetic separators. Introduction: Permanent magnets offer superior strength and reliability and are designed for separation of ferrous metal from a variety of belt conveyed products. Their heavy industrial design and construction make them ideal for use in foundry , recycling, fire shredding, wood chip, and demolition applications. Features:

Optional features:

The removal of tramp metal can create many challenges and is dependent upon many factors. These in include product size, density, moisture, tramp metal geometry, orientation, magnet suspension height, entrapment by large product pieces, location the burden, and many others. Let star trace help you assess your application and solve your metal separation needs with a properly selected magnet. Self-cleaning magnets:

Manual clean magnets:

Note: Technical data and specification subject to change. Special over band permanent magnetic separator can be made on request, customers have to just send their technical data and application required for our engineers. keyword tag: Overband permanent magnetic separators, overband permanent magnetic separator, manufacturer of overband permanent magnetic separator, manufacturer of overband permanent magnetic separators, supplier of overband permanent magnetic separators and overband permanent magnetic separators in india. |

![]()

Liquid Line Magnetic Separators

![]()

![]()

| We manufacture liquid line magnetic separators that are designed for use in heavy duty, large volume liquid & semi-liquid line flow systems. It employs a slip-in cage made of stainless steel permanent magnetic tubes that capture ferrous tramp metal particles & improve the product's purity. The range of our liquid line magnetic separators can be availed in 7 standard line sizes ranging between 2' to 18' in diameter. We can also custom manufacture them as per the special needs of the customers. It allows the products to flow through the housing without bridging of the products. Using an interior baffle the product flow is directed towards the plate magnet. These liquid line magnetic separators can be installed in any position, whether vertical position that eliminates the sump area or horizontal to make cleaning easier. keyword tag: Liquid line magnetic separator,liquid line magnetic separators, manufacturer of liquid line magnetic separator, manufacturer of liquid line magnetic separators, supplier of liquid line magnetic separators, liquid line magnetic separators in India, exporters of liquid line magnetic separators, liquid line magnetic separators manufacturers, liquid line magnetic separators suppliers, liquid line magnetic separators exporters, liquid line magnetic separators manufacturing companies, liquid line magnetic separators in Chennai, liquid line magnetic separators supplier in India and liquid line magnetic separators in Chennai. |

![]()

Eddy Current Separators

![]()

![]()

| Star trace is a highly known and established manufacturer and supplier of Eddy current separators , which are ready to be installed in your separation facility. This separator uses a highly powerful eddy current separators, conveyor belt, two variables discharge area and support frame. The optional vibratory feeder provides a consistent flow of material to the eddy current separators. These top-class non-ferrous eddy current separators are highly reliable, durable, high performing and available at reasonable prices. Our eddy current separators is manufactured using the best quality raw materials to ensure satisfaction of customers. These eddy current separator devices are perfect and effective work for removing non - ferrous metals from other products. Applications of eddy current separators are aluminum cans from municipal waste, aluminum flakes from shredded pet, brass and aluminum from foundry sands, and metals from shredded automobile scrap. Other metals, such as lead can also be removed. For successful non-ferrous separation, a magnet should be installed prior to an eddy current separators. Eddy current rotor: Star trace eddy current rotor utilizes an alternate magnetic field for producing electrical currents in conductive metal. The electrical current produces its own magnetic field around an object, which opposes the magnetic field from the eddy current. This repulsion diverts the object from the product stream. Mass, conductivity and density influence the force and distance an object will repel. Eddy current separation system: Eddy current separation system manufactured and supplied by star trace encompasses all the equipments above necessary to separate non - ferrous metals and add ferrous metal separation equipment. It is significant for removing ferrous metal prior to exposure to the eddy current separators. Strong magnetic field magnetizes and holds ferrous metal. The ferrous metal will heat up and could burn holes in belt and cause significant damage to the eddy current rotor. Note: Technical data and specification subject to change. Special non ferrous eddy current metal detector can be made on request of customers, they have to just send technical data and application, required for our engineers. keyword tag: Eddy current separator, eddy current separators, manufacturer of eddy current separator, manufacturer of eddy current separators,supplier of eddy current separators, eddy current separators in India, exporters of eddy current separators, eddy current separators manufacturers, eddy current separators suppliers, eddy current separators exporters, eddy current separators manufacturing companies, eddy current separators in Chennai, eddy current separators supplier in india, eddy current separators in Chennai, eddy current separators manufacturer in india, eddy current separators India, eddy current separators manufacturers in India and Indian manufacturers of eddy current separators. |

![]()

Wet High Intensity Magnetic Separators

![]()

![]()

| We at star trace are recognized manufacturer, supplier of wet high intensity magnetic separator (whims). Wet high intensity magnetic separator designs, develops, manufactures and markets magnetic separation equipment for beneficiating weakly magnetic minerals, and for purifying non-metallic minerals. Star trace professionals have specializes in the field of magnetic separation technology. We have been manufacturing and supplying these equipments since 1983. It became a leading supplier of whims in india in 1980s, and it has become a leading supplier of high gradient magnetic separators since 1990s. Applications: Star trace on vphgms is suitable for processing fine, weakly magnetic minerals, such as hematite, limonite, ilmenite, manganese, wolframite, tantalum-niobium, and etc. It is also suitable for removing iron and titanium from non-metallic minerals such as quartz, feldspar, nepheline, fluorite, ceramic material, and etc. our company vertical ring and pulsating high gradient magnetic separator uses combined force field of magnetism, pulsating fluid and gravity to beneficiate weakly magnetic minerals with the advantages of large beneficial ratio, high recovery, matrix not easy to be blocked and excellent performance. The star trace on-1000, stpl-1250, stpl-1500, stpl-1750, stpl-2000 and stpl-2500 have developed. The maximum feed capacity is up to 120t/h. Owing to its unique design and its excellent performance for mineral beneficiation, stpl vphgms has successfully applied in several industries. Note: Technical data and specification subject to change. Special wet high intensity magnetic separator can be made on request, customers have to just send their technical data and application required for our engineers. keyword tag: Wet high intensity magnetic separator, manufacturer of wet high intensity magnetic separator, manufacturers in india and indian manufacturers of wet high intensity magnetic separators. |

![]()

High Intensity & High Gradient Drum Separators

![]()

![]()

| These type of high intensity drum separators, high gradient drum separators are extensively used in:

These machines are also used in the processing industry for separating iron contamination from the following:

Size range:

Salient features:

|

![]()

High Intensity & High Gradient Roll Separators

![]()

![]()

| Our company was the pioneer in the manufacturing of indigenous high intensity & high gradient roll separators. These are extensively used for dry material in the domestic market and can separate different types of materials in diverse industries efficiently & economically. Our company makes use of high energy rare earth neodymium permanent magnets, which are assembled in a proprietary configuration. This configuration generates a force of magnetic attraction that can be utilized for processing different materials from ferromagnetic to weakly paramagnetic. keyword tag: High intensity & high gradient roll separators,high intensity & high gradient roll separatorss, manufacturer of high intensity & high gradient roll separators, manufacturer of high intensity & high gradient roll separatorss,supplier of high intensity & high gradient roll separators,high intensity & high gradient roll separators in india, exporters of high intensity & high gradient roll separators,high intensity & high gradient roll separators manufacturers,high intensity & high gradient roll separators suppliers,high intensity & high gradient roll separators exporters, high intensity & high gradient roll separators manufacturing companies, high intensity & high gradient roll separators in chennai, high intensity & high gradient roll separators supplier in india, high intensity & high gradient roll separators in chennai, high intensity & high gradient roll separators manufacturer in india,high intensity & high gradient roll separators india, high intensity & high gradient roll separators manufacturers in india, indian manufacturers of high intensity & high gradient roll separators, high intensity & high gradient roll separators indian supplier. |

![]()

High Tension Electrostatic Drum Separators

![]()

![]()

| We are established company involved in designing, developing and supplying excellent quality Industrial Electrostatic separator and offer it at market leading prices. Electrostatic drum separators are designed for separating mixtures of bulk materials, which are differing by their electrical properties. These superior quality high tension electrostatic drum separator are manufactured following international norms and standards to satisfy the customers and maintaining products quality. Features: This high tension electrostatic drum separator is capable of producing high grade concentrators with fast recovery of valuables owing to three -step re-cleaning and facility for heating materials. Besides these feature, it also consumes little electric power and is environment-friendly. Application:

For Technical Specifications Click for PDF KeyWord Tag:High Tension Electrostatic Drum Separators,High Tension Electrostatic Drum Separator,Manufacturer of High Tension Electrostatic Drum Separator, Manufacturer of High Tension Electrostatic Drum Separators,Supplier of High Tension Electrostatic Drum Separators,High Tension Electrostatic Drum Separators in India, Exporters of High Tension Electrostatic Drum Separators,High Tension Electrostatic Drum Separators manufacturers,High Tension Electrostatic Drum Separators suppliers,High Tension Electrostatic Drum Separators exporters,High Tension Electrostatic Drum Separators manufacturing companies,High Tension Electrostatic Drum Separators in Chennai,High Tension Electrostatic Drum Separators Supplier in India,High Tension Electrostatic Drum Separators in Chennai,High Tension Electrostatic Drum Separators manufacturer in India,High Tension Electrostatic Drum Separators India ,High Tension Electrostatic Drum Separators manufacturers in India,Indian manufacturers of High Tension Electrostatic Drum Separators,High Tension Electrostatic Drum Separators Indian supplier, |

![]()

Cyclic Magnetic Separators

![]()

![]()

| We are one of the pioneer companies engaged in manufacturing and supplying the most celebrated quality of cyclic magnetic separators, which are made from superior quality raw materials for outstanding performance of products. Our company, Star Trace has well-educated and experienced professionals who carefully implementing latest technology and modern machines to ensure quality products and customers’ satisfaction. These best performing products are available at very economic prices. Specifications: Star Trace-HGMS Magnetic separators include magnetic assembly separators include magnetic (magnetic coil, magnetic return frame), canister with matrix and support structure, process flow distribution system, process controller and instrumentation. A closed loop cooling system may be provided for the magnet and power supply if suitable cooling water is not available. The system is provided with a fail-safe protection through thermal switches and a flow switch in the main cooling system; fail safe alarm triggering circuitry, operational in the events of component failure; and external interlocks to protect the system in the event of equipment failure. Power supply (rectifier) is built in accordance with the customer’s requirements (voltage, frequency). Appropriate feed system and means for product collection and handling are provided by the customer or are available. Applications & Purification: Star Trace-HGMS magnetic separators have capability to remove even very weakly paramagnetic materials. A number of extremely effective applications include: Clay Benefits: High gradient magnetic separator is unique in its ability to brighten clays be removing fine, weakly magnetic color body particles. This new technology may be used for:

Manufacturing industry, power generation:

Industrial and waste waters:

Chemical, food and petroleum industries: Applications exist for STR HGMS magnetic separator in the filtration of pregnant liquors, recovery and purification of catalysts (wet or dry), other valuable materials. Concentration: Successful beneficiation to final quality products has been proved for rare earth minerals, beach sands and other minerals. Note: Technical data and specification subject to change. Special cyclic magnetic separator can be made on request, customers have to just send their technical data and application required for our engineers. Key Word Tag: Cyclic Magnetic Separator, Cyclic Magnetic Separators,Manufacturer of Cyclic Magnetic Separatorss, Supplier of Plate Magnet, Cyclic Magnetic Separatorssin India, Exporters of Cyclic Magnetic Separatorss, Cyclic Magnetic Separatorss manufacturers, Cyclic Magnetic Separatorss suppliers, Cyclic Magnetic Separators exporters, Cyclic Magnetic Separatorss manufacturing companies, Cyclic Magnetic Separators sin Chennai, Cyclic Magnetic Separators supplier in India, Cyclic Magnetic Separatorsin Chennai, Cyclic Magnetic Separatorss manufacturer in India, Cyclic Magnetic Separatorss India , Cyclic Magnetic Separatorss manufacturers in India, Indian manufacturers of Cyclic Magnetic Separatorss, Cyclic Magnetic Separators Indian supplier, |

![]()

Concentrator Separators

![]()

![]()

| We are one of the leading manufacturers and suppliers of the highest quality concentrator separator, which are manufactured using the finest quality raw material to ensure quality of products and customers’ satisfaction. Application: Permanent magnetic concentrator separator is extensively used for advancing or concentrating material containing a very high percentage of magnetic or where magnetic/mechanical agitation is required for the separation of many difficult materials. It is perfect for the improving sponge iron/cast iron borings, steel/brass aluminum turnings, chips and for mineral beneficiation application such as the purification of dry ceramic and refractory materials, reclamation of abrasive grains, removal of iron contamination from chemical powders and grains and for many other such applications requiring maximum separation with minimum production loss etc. Description: The separator basically consists of:

The material to be treated is fed from the vibratory feeder on to lower belt where after traveling a short distance it comes under the belt conveyor. The upper belt conveyor runs under a series of powerful concentrator separator arranged in such a manner so that the material is exposed during its travel through a number of magnetic fields of alternating polarity. Due to the continuous repetitive agitation of the material nonmagnetic material falls back on to the lower conveyor belt, while the magnetic material is retained on the upper conveyor belt due to the force of magnetic attraction. The separated material are carried and deposited into the respective magnetic and non-magnetic discharge chutes. Manufacturing range: The concentrator separator is available in a wide range of sizes and capacities up to approx. 100 tph and 650mm belt width up to 2000mm belt width. Options available at extra price:

Note: Technical data specification subject to change. Special concentrator separator can be made on request, customers have to just send us their technical data and application. keyword tag: Concentrator separator, concentrator separators, manufacturer of concentrator separator, manufacturer of concentrator separators, supplier of concentrator separators, concentrator separators in India, exporters of concentrator separators, concentrator separators manufacturers and concentrator separators suppliers. |

![]()

Suspension Electromagnets

![]()

![]()

| We are one of the leading manufacturers and suppliers of the highest quality suspension electromagnets, which are machined using most reliable raw materials to ensure excellence of products. These suspension electromagnets are manufactured by highly qualified and experienced professionals who always strive for perfection of products. These electromagnetic suspensions offered by us are sent for stringent quality check-up before supplying to the customers to ensure their satisfaction. Our range of suspension electromagnets is easily and cheaply accessible in the markets. Benefits:

Introduction: Our suspension electromagnets are designed for separating of ferrous metal from a variety of over- the- belt conveyor purposes. Proven in industries such as mining, recycling, tire shredding, pulp & paper and construction & demolition. Star trace’s suspension electromagnets offer superior strength and reliability. These suspension electromagnets are used in high volume low (less than 150mm) product depth applications, suspended electromagnets offer “deep reach” capacity and the ability to be turned on & off. Installation options include in-line and cross-belt configurations to meet the specific needs of your applications. Operation: As the product on a conveyor belt runs under the powerful magnetic field, ferrous material is pulled out of the product flow and held to the face of the magnet. While using a manual-clean model, the collected tramp metal is held in place for as long as the unit has power. For cleaning the unit, the power source must simply be turned off, which instantly releases the metal from the magnets hold. With self-cleaning models, continuous cleaning is made possible by a heavy duty clad belt that encircles the magnet on a series of rotating pulleys. As ferrous metal is attracted and held by the magnet, the moving belt carries the collected metal outside of the magnetic field where it is then released beyond the product flow. Options:

Specifications:

Note: All dimensions are stated in mm. Note: Technical data specification subject to change # electro magnet can be made on request of customers, they have to just send us their technical data and application, required for our engineers. keyword tag: Suspension electromagnet, suspension electromagnets, manufacturer of suspension electromagnet, manufacturer of suspension electromagnets, supplier of suspension electromagnets, suspension electromagnets in India, exporters of suspension electromagnets, suspension electromagnets manufacturers, suspension electromagnets suppliers, suspension electromagnets exporters and suspension electromagnets manufacturing companies. |

![]()

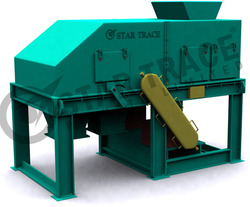

Electro Magnetic Scrap Drum Separator

![]()

![]()

| We are a pioneer name engaged in manufacturing and supplying advanced electromagnetic scrap drum separator. Star trace always offers highest quality products, which are engineered by our skilled team of technocrats using superb quality raw materials. Electromagnetic scrap drum separator opens the way to new efficiency in handling big volumes of large-sized material encountered in today’s material processing and mineral concentration applications.

Features

|

![]()

Wet Drum Separator

![]()

![]()

| Introduction Stl is one of the leading manufacturers of ore dressing equipment. The present range of stl process equipment enables us to provide complete packages. Magnetic wet separators constitute an important part of the product range and are known for advanced engineering design and excellent performance. As a result of continuous development in separator technology stl can offer a complete line of magnetic wet separators to the mining and mineral industries. Product models and sizes Stl's wet permanent magnetic separators are offered in sizes of dia. 1200 mm and 916mm in lengths of up to 3000mm. Three basic separator designs are available for cobbing, roughing and finishing/cleaning applications. Each type can be supplied in single drum or multiple drum stages of taconite or magnetite and also for recovery for magnetic medium in dense media plants. The stationary magnet yoke is an assembly of strontium-ferrite permanent ceramic magnets. The rotating drum is available with optional rubber or stainless steel covers. The magnetic flux pattern will match the tank configuration for optimum performance. Stl's magnetic wet separator dia 916 x 300 mm is the smallest full scale separator in the 916 series and is primarily used for pilot plant tests. The separator can be delivered in concurrent, countercurrent and counter rotation versions. Stl's magnetic wet separator for laboratory use have drum dimensions dia. 600 x 285 mm and dia. 200 x 100 mm and are suitable for batch or continuous testing. The test results from the stl laboratory.

the drum shell is made of non-magnetic stainless steel with abrasion-resistant wear cover and sealed heads of cast rigid aluminium alloy. The drum shaft runs in spherical, self-aligning anti-friction bearings. Adjustment of magnet yoke and drum The magnet yoke is mounted on the stationary drum shaft and its position can be adjusted (+/-35) by a lever at the end of the drum shaft to optimize runing conditions in accordance with tank design and type of ore. The gap between tank and drum, which determines the pulp flow speed, can be adjusted vertically by shims inserted under the bearing housing and shaft support. Horizontal adjustment is by slotted holes. keyword tag: Wet drum separator, wet drum separators,manufacturer of wet drum separator, manufacturer of wet drum separators, supplier of wet drum separator, wet drum separator in india, exporters of wet drum separator, wet drum separator manufacturers, wet drum separator suppliers, wet drum separator exporters, wet drum separator manufacturing companies and wet drum separator in chennai. |

![]()

|

Contact Us

|

Home | About Us | Our Products | Send Enquiry | Site Map | Contact Us

Copyrights © 2012. Star Trace Private Ltd, Chennai. All Rights Reserved.